control valve

CVG1-Plug Type Globe Control Valves

Reliable

Tough guiding of the plug promotes maximum valve stability under adverse conditions. The inherent ruggedness of the CGV1 Series is field-proven, with several of units installed in process control plants around the world operating successfully with various fluids under mild and extreme conditions.

Trim

single seat plug top guided; Lo-dB and anti-cavitation trims,

linear or equal percentage

High Performance

The combination of trim designs, actuator stability, shutoff capabilities, and superior valve positioning offers optimum control performance. The CGV1 Series is also available in various materials, pressure ratings, and end connections offering a complete high-performance valve platform

Size

3/4” through 8”

Body Materials

carbon steel; stainless steel; chrome-moly

Ratings & Connections

Flanged: ANSI 150 – 2500

Welded: BW or SW

Screwed: NPT 3/4” through 2”

Actuators

MSD/SSC model, multi-spring diaphragm; cylinder are Available

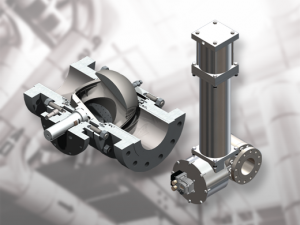

CVG2-Cage Type Globe Control Valves

Reliable

Reliable performance with standard solutions to control noise, cavitation, and valve leakage improving plant operating efficiency

Trim

balanced cage-guided trim; Lo-dB, anti-cavitation, single and multiple cages are available

linear or equal percentage

Description

The AMP CVG2 Series heavy duty control valve features balanced trim configurations. This product line offers efficient and stable operation under demanding process conditions, including applications with high-pressure drops and large temperature variations. Optional features include noise attenuation trim, anti-cavitation designs, and various balance seal options to meet a wide range of pressure and temperature requirements

Size

2” through 24”

Body Materials

carbon steel; stainless steel; chrome-moly

Ratings & Connections

Flanged: ANSI 150 – 2500

Welded: BW or SW

Screwed: NPT 2”

Actuators

MSD/SSD/SSC model, multi-spring diaphragm; Single-Spring diaphragm; cylinder are Available

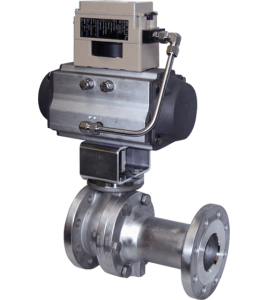

CVB2-Two Piece Control Ball Valves

Reliable

Reliable performance with standard solutions to control noise, cavitation.

Trim

AMP CVB2 control ball valves are in compliance with IEC 60534; other international standards or customer specifications are available on request. it is possible to choose over a wide range of materials to meet the process conditions. to ensure a long service life many different coatings are available to prevent ball and seats from damage due to erosive flow and continuous operation. customer can choose between pneumatic (double acting or spring return), electric or hydraulic actuators.

Description

The AMP CVB2 Series heavy duty control valve features balanced trim configurations. This product line offers efficient and stable operation under demanding process conditions, including applications with high-pressure drops and large temperature variations. Optional features include noise attenuation trim, anti-cavitation designs, and various balance seal options to meet a wide range of pressure and temperature requirements

Size

1″ through 12“

Body Materials

Carbon steel Stainless steel

Ratings & Connections

Flanged: ANSI 150 – 300

Actuators

Pneumatics, electrohydraulic and electric actuator available

CVB3-Three Piece Control Ball Valves

Reliable

Reliable performance with standard solutions to control noise, cavitation, and valve leakage improving plant operating efficiency

Trim

AMP CVB2 control ball valves are in compliance with IEC 60534; other international standards or customer specifications are available on request. it is possible to choose over a wide range of materials to meet the process conditions. to ensure a long service life many different coatings are available to prevent ball and seats from damage due to erosive flow and continuous operation. customer can choose between pneumatic (double acting or spring return), electric or hydraulic actuators.

Description

The AMP CVB3 Series heavy duty control valve features balanced trim configurations. The CVB3 rotary control valve offers high-capacity, heavy-duty automatic throttling capability. This product line offers efficient and stable operation under demanding process conditions, including applications with high-pressure drops and large temperature variations. Optional features include noise attenuation trim, anti-cavitation designs, and various balance seal options to meet a wide range of pressure and temperature requirements

Size

1″ through 12“

Body Materials

Carbon steel Stainless steel

Ratings & Connections

Flanged: ANSI 150 – 300

Actuators

Pneumatics, electrohydraulic and electric actuator available

CVF2-Double Offset Control Butterfly Valves

Reliable

The balance of this valve is in the stem placed behind the circular disc. It allows the disc to self-adjust to the center, ensuring tight sealing. Even when the valve is fully opened, the valve does not touch the soft seat, ensuring a longer service life.

Trim

Double eccentric TFE, RTFE, and flexible metal seals offer Class IV (metal) or Class VI (PTFE / RTFE) shut-off

Description

The AMP CVF2 Series heavy duty control valve features balanced trim configurations. Low torque, double offset disc improves control performance and reduces seal wear for longer operating cycles and reduced maintenance.

Size

3″ through 48“

Body Materials

Carbon steel Stainless steel

Ratings & Connections

Flanged: ANSI 150 – 600

Actuators

Pneumatics, electrohydraulic and electric actuator available

CVF3-Thriple Offset Control Butterfly Valves

Reliable

As a butterfly valve, it also belongs to the quarter family. It is also lightweight and easy to operate. Installation is also a breeze since there is less pipe bracing needed. Replacement of seat rings is also easy as this valve is top-entry.

The triple offset butterfly valve has a low torque so there is no need to have larger valves. That being said, this means higher savings costs. This valve has zero leakage closure on both ends.

The introduction of soft seats increases the value of the valves. Aside from being fire-safe due to the metal seats underneath the soft ones, the valves can now self center because of the elastomeric seat material. Trim

Double eccentric TFE, RTFE, and flexible metal seals offer Class IV (metal) or Class VI (PTFE / RTFE) shut-off

linear or equal percentage

Description

The AMP CVF3 Series heavy duty control valve features balanced trim configurations . Low torque, Triple offset disc improves control performance and reduces seal wear for longer operating cycles and reduced maintenance.

Size

3″ through 48“

Body Materials

Carbon steel Stainless steel

Ratings & Connections

Flanged: ANSI 150 – 600

Actuators

Pneumatics, electrohydraulic and electric actuator available